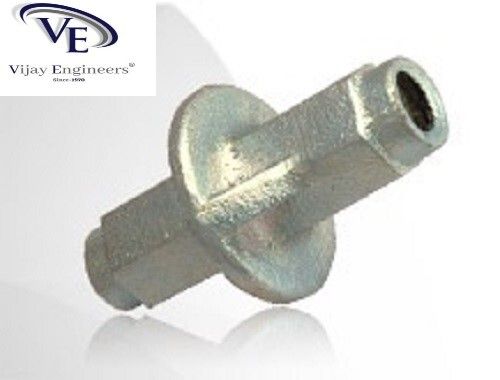

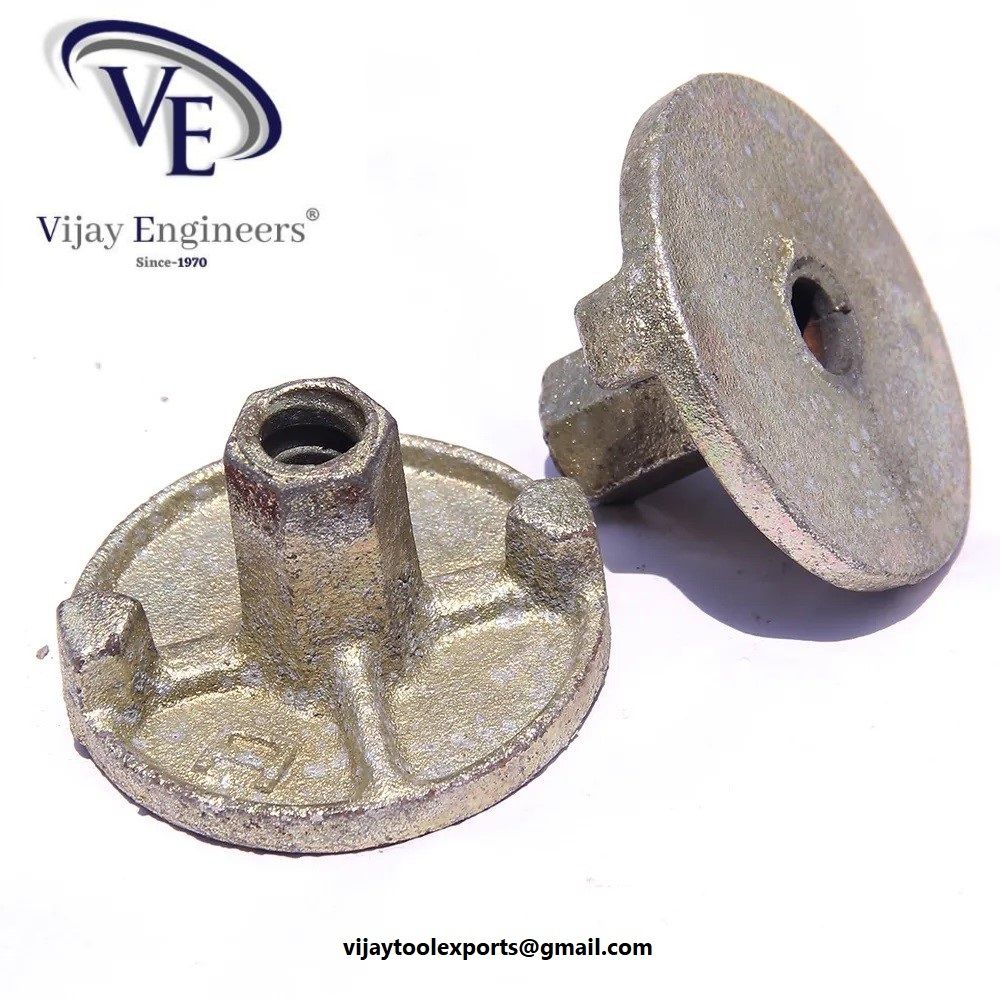

ANCHOR NUT IN LIBYA

Price 28 INR/ Piece

ANCHOR NUT IN LIBYA Specification

- Features

- Rust Resistant, High Durability, Precision Engineered

- Technique

- Hot Forged

- Prop Head

- Adjustable

- Pin

- Included

- Color

- Silver/Grey

- Sleeve size

- M16, M18, M20

- Constitute

- Body, Threads, Pin Hole

- Weight

- 0.4 kg

- Product Type

- Scaffolding Anchor Nut

- Material

- Ductile Iron

- Components

- Anchor Nut

- Diameter

- 12 mm

- Width

- 30 mm

- Length

- 50 mm

- Height

- 24 mm

- Thickness

- 6 mm

- Platform Loading Capacity

- Up to 250 kN

- Surface Treatment

- Galvanized, Zinc Plated

- Application

- Scaffolding, Formwork, Construction

- Size

- Standard

- Standard

- EN 74/BS 1139

- Corrosion Resistance

- Yes

- Packing Type

- Gunny Bag or Carton

- Thread Type

- Coarse/Fine

- Installation Method

- Manual Tightening

- Working Temperature

- -20°C to +60°C

- Usage

- Reusable

- Shape

- Three Wing/Butterfly

- Breaking Load

- Minimum 100 kN

About ANCHOR NUT IN LIBYA

Top Leading Manufacturer & Exporter of Scaffolding & Formworks

WITH FAST DELIVERY AND BEST QUALITY

Bolts Nuts Washers

DROP FORGED FIXED/DOUBLE COUPLER

DROP FORGED SWIVEL COUPLER

PRESSED STEEL FIXED/DOUBLE COUPLER

PRESSED STEEL SWIVEL COUPLER

TIE ROD

WING NUT

ANCHOR NUT (2 WING & 3 WING )

#scaffolding #project #contractorlife #constructionsolutions #constructionindustry #concreteconstruction #civilengineering #projectcontrol #civilengineers #chinascaffolding #scaffoldingsupply #safetyfirst #safetyawareness#export #exports #sales #imports #formworks #projectsuccess #projectmanagment #constructioncompany #andamio #scaffoldingservices #swivelcoupler #fixedcoupler #tierod #ledgerblade #topcup #doka #peri #alsina #accrow #dywidag #tubes #bottomcup #wingnut #waterstopper #clamps #jacks #exporter #importer #design #engineering #china #india #manufacturing #bestproducts #bestqualityproduct #germany #egypt #UAE #kenya #tanzania #kuwait #qatar #canada #saudiarabia #oman #dubai #cyprus #turkey #exporting #importing #building #construction #couplers #clamps #projects #building #manufacturing #contractors # #steel #gas #oilindustry #oilandgas #oilfield #oilandgasindustry #maintainance #importers #buyers #agents #agentcommercial #supply #ringlock #cuplock

#export #exports #sales #imports #formworks #projectsuccess #projectmanagment #constructioncompany #scaffolding #project #contractorlife #constructionsolutions #constructionindustry #concreteconstruction #civilengineering #projectcontrol #civilengineers #chinascaffolding #scaffoldingsupply #safetyfirst #safetyawareness #andamio #scaffoldingservices #swivelcoupler #fixedcoupler #tierod #ledgerblade #topcup #doka #peri #alsina #accrow #dywidag #tubes #bottomcup #wingnut #waterstopper #clamps #jacks #exporter #importer #design #engineering #china #india #manufacturing #bestproducts #bestqualityproduct #germany #egypt #UAE #kenya #tanzania #kuwait #qatar #canada #saudiarabia #oman #dubai #cyprus #turkey #exporting #importing #building #construction #couplers #clamps #projects #building #manufacturing #contractors # #steel #gas #oilindustry #oilandgas #oilfield #oilandgasindustry #maintainance #importers #buyers #agents #agentcommercial #supply #ringlock #cuplock

Precision Engineering and Robust Durability

Our Anchor Nuts are manufactured through a hot forging process, ensuring uniformity, strength, and precise thread formation. The ductile iron base, combined with galvanized or zinc-plated surfaces, provides long-term protection against rust and environmental corrosion, making them ideal for the diverse climatic conditions found in Libya.

Versatile Usage Across Construction Projects

Designed for both new builds and maintenance projects, these anchor nuts offer compatibility with various scaffolding and formwork systems. Adjustable prop heads and sleeve sizes extend application flexibility, while their reusable construction significantly reduces replacement costs. Suitable for supporting platform loads up to 250 kN, they are trusted by contractors, exporters, and suppliers across the region.

FAQ's of ANCHOR NUT IN LIBYA:

Q: How are anchor nuts installed in scaffolding and formwork systems?

A: Anchor nuts are installed manually by tightening them onto threaded rods or props, using the three-wing or butterfly design for easy grip and torque application. No specialized tools are required, ensuring quick and secure installation in construction environments.Q: What benefits does the galvanization or zinc plating offer to anchor nuts?

A: Galvanization and zinc plating provide robust corrosion resistance, protecting the anchor nuts from rust and harsh weather conditions in both indoor and outdoor construction projects in Libya. This increases their lifespan and reliability.Q: When should I choose coarse versus fine thread types for my anchor nuts?

A: Coarse threads are typically chosen for faster assembly and disassembly, especially in environments with dust or debris, while fine threads provide greater holding power and are suitable for applications requiring precise tension control.Q: What is the process behind manufacturing these anchor nuts?

A: Each anchor nut is manufactured through a hot forging technique, which shapes the ductile iron into exact specifications. This process ensures the final product meets strict EN 74/BS 1139 standards and offers superior strength and durability.Q: Where can anchor nuts be utilized within a construction project?

A: Anchor nuts are versatile and can be used in scaffolding, formwork, and other temporary support systems across commercial, industrial, and residential construction sites. Their adjustable design allows quick adaptation to different structural requirements.Q: What makes these anchor nuts reusable in various projects?

A: Their robust construction, corrosion resistance, and precise threading allow them to be safely unscrewed and reused across multiple scaffolding and formwork setups, reducing material costs while supporting sustainable practices in construction.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MS Scaffolding Category

PROP NUT IN LIBYA

Price 40 INR / Piece

Minimum Order Quantity : 1000 Kilograms

Size : Fits 60 mm prop tube

Application : Other, Scaffolding and shuttering system

Material : Other , Forged or cast steel

Surface Treatment : Other, Galvanized / Painted

CI GUGU NUT

Price 18 INR / Piece

Minimum Order Quantity : 1000 Kilograms

Size : 48 mm

Application : Other, Scaffolding, Formwork

Material : Other , Cast Iron

Surface Treatment : Other, Galvanized / Painted

WATER STOPPER IN MUMBAI

Price 29 INR / Piece

Minimum Order Quantity : 1000 Kilograms

Size : Standard & customized

Application : Other, Used in shuttering to stop concrete leakage and prevent water seepage

Material : Other , Mild Steel

Surface Treatment : Other, Galvanized / Powder Coated

WING NUT IN PUNE

Price 16 INR / Piece

Minimum Order Quantity : 1000 Kilograms

Size : M6, M8, M10, M12, M16, M20 & Custom sizes

Application : Other, Industrial Fastening, Furniture, DIY, Construction

Material : Other , Mild Steel, Stainless Steel, Brass

Surface Treatment : Other, Galvanized, Zinc Plated, SelfColour

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry